Solution

Introducing Ene-Conductor for Industrial Optimization

Ene-Conductor automates heat source equipment control, reducing energy costs by 30% and improving operational efficiency.

FEATURES

1. Key Energy Challenges for Southeast Asia's Manufacturing Industry

Is your factory struggling with high energy costs and inefficient energy management—challenges commonly faced by manufacturers in Southeast Asia? For manufacturers in ASEAN, industrial energy efficiency is no longer optional—it is a critical factor for cost reduction and business competitiveness.

Rising Energy Costs in Southeast Asia

Energy costs in Southeast Asia are becoming a critical issue for businesses, particularly in the industrial

sector.

The 8th ASEAN Energy Outlook (AEO8), published by the ASEAN Centre for Energy (ACE), highlights a significant

rise

in energy demand across the region. According to the report, the industrial sector alone is expected to consume

561.0 Mtoe* by 2050, with coal (39.6%), electricity (22.4%), and natural gas (14.5%) as the primary energy

sources.

*tonne of oil equivalent

Overreliance on Individual Skills and Manual Processes

Is your factory overly dependent on the experience and intuition of specific individuals, resulting in frequent manual adjustments and reduced operational efficiency?

Frequent Equipment Failures Leading to Unstable Production Lines

Are unexpected equipment failures occurring due to inadequate early detection, resulting in sudden production line stoppages and emergency responses?

2. How Ene-Conductor Solves These Challenges

Mitsubishi Heavy Industries Thermal Systems' "Ene-Conductor" is an advanced energy optimization solution that seamlessly automates real-time thermal energy management for factories. ✓ Optimal control maximizing centrifugal chiller performance ✓ Coordinates multiple chillers for optimal energy savings ✓ Intelligent, real-time optimization algorithms that quickly adapt to changing conditions

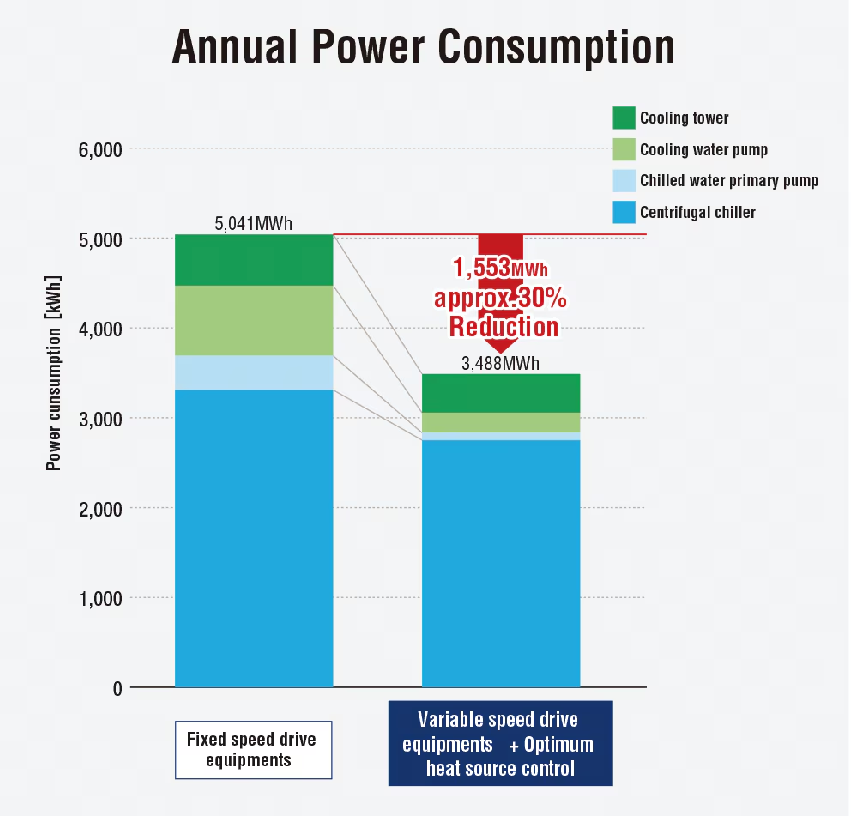

3. Save 30% Energy Costs with Ene-Conductor

Achieve approximately 30% energy cost reduction eliminate unnecessary energy use through precise, real-time automatic control.

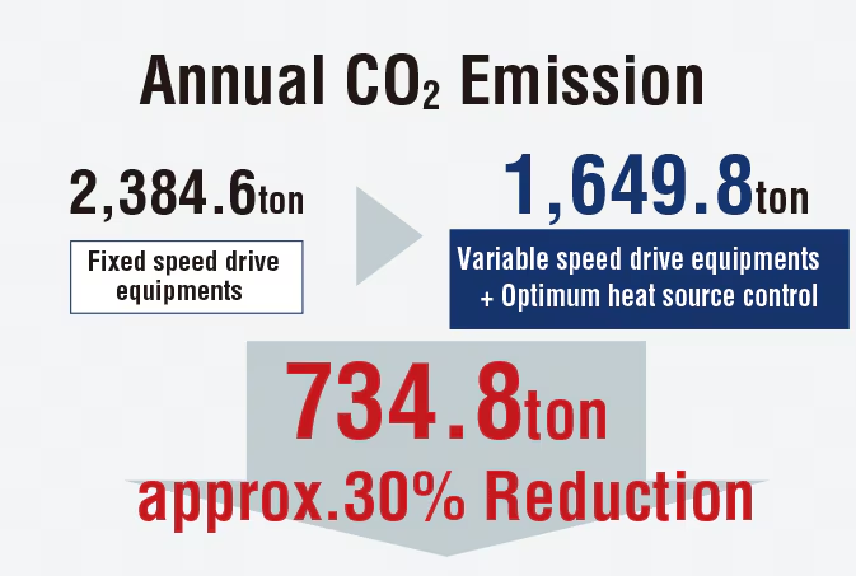

Transition from individual-dependent operations minimize manual adjustments, reduce operational burden, and consistently achieve stable operations.

Enhance corporate value by reducing CO₂ emissions significantly reduce CO₂ emissions, enhancing corporate value by fulfilling social responsibilities.

4. Real-World Success : Sony’s Energy Optimization with Ene-Conductor

Sony Device Technology (Thailand) Co., Ltd. achieved a 30% energy savings by integrating Ene-Conductor into its factory energy management system.

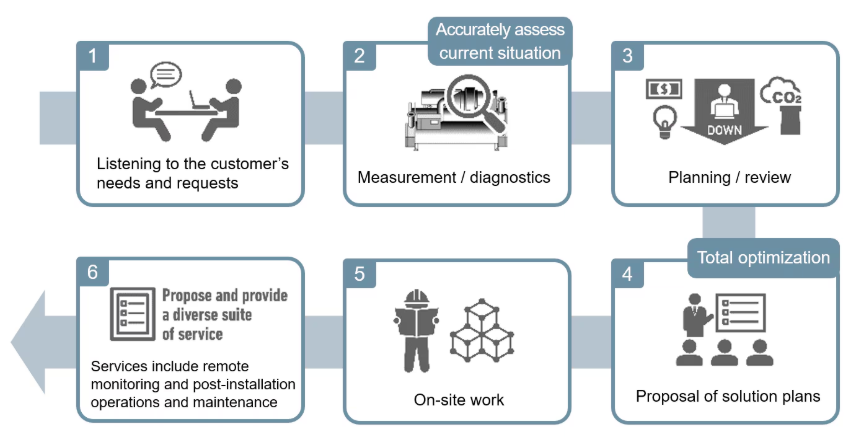

5. Quick Setup: Seamless Ene-Conductor Implementation

Ene-conductor supports businesses in achieving smooth implementation of improvement, and addressing challenges such as energy optimization and reduction of power consumption. Mitsubishi Heavy Industries Thermal Systems will consult whether investments gain return rapidly, and comprehensively support stable operations and reduction unexpected equipment failures under amid labor shortage.

For businesses aiming for stable and efficient energy management, reduced unexpected equipment failures, and comprehensive energy optimization, we offer free energy-saving diagnostics.