Solution

Custom design and supply meeting high efficiency through integrated control of heating and cooling source systems

Improving PUE boosts data center competitiveness. MHI Thermal Systems’ Centrifugal chiller using advanced technologies contributes to boost efficiency of AC equipment, whose power usage at data centers is second only to IT equipment, with Ene-Conductor to optimally control Centrifugal chillers.

FEATURES

Maximizing the performance of heat source equipment under all conditions

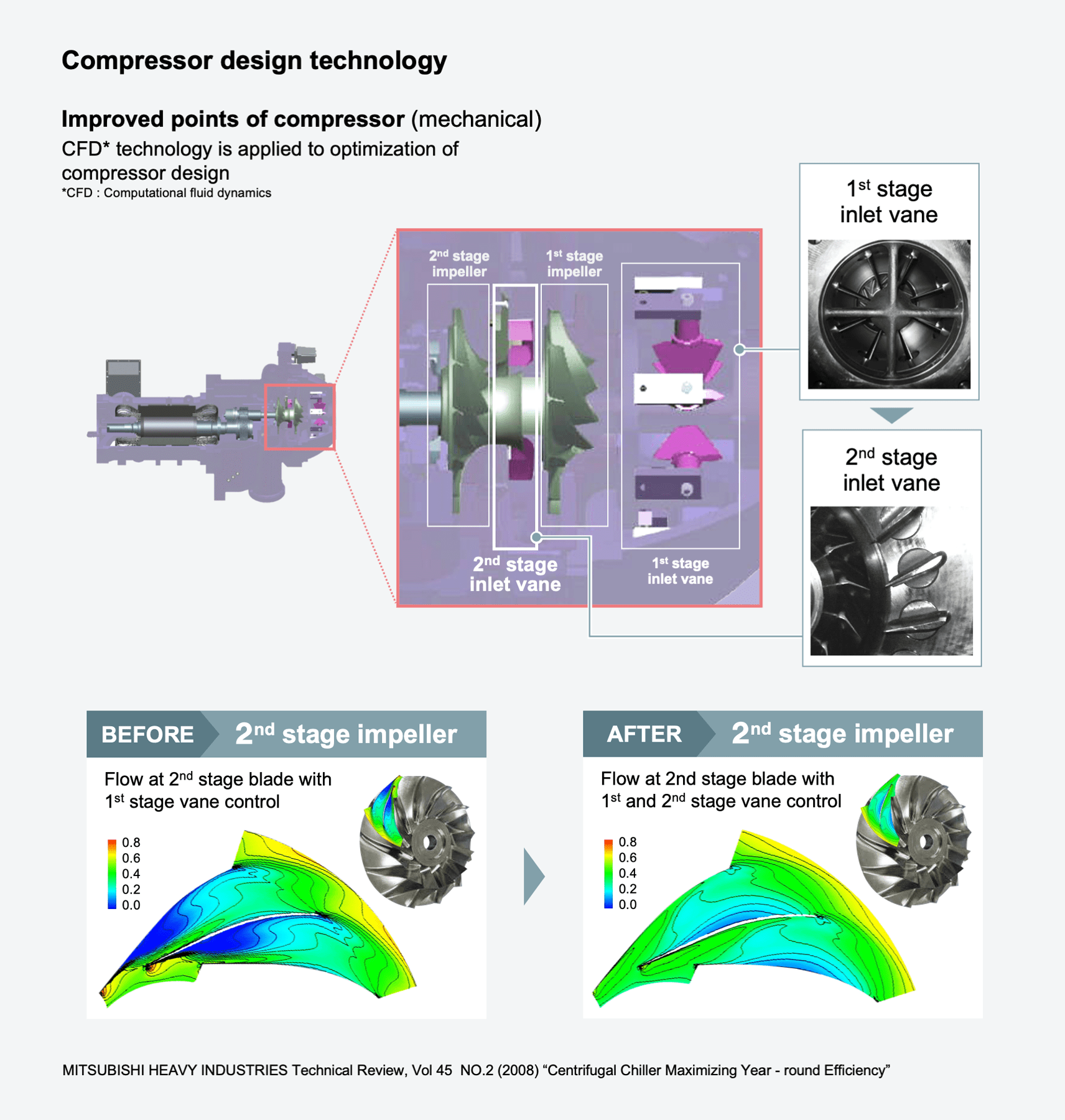

For compressors, which form the heart of chiller units, we apply the same technologies used in the design of commercial gas turbines, which have an extensive track record of use around the world, and the compressors used at petrochemical plants. We employ aerodynamic analysis technologies to improve the flow inside impellers and downstream of outlets to improve efficiency across a wide range of capacities. One- and two-stage vanes that adjust impeller shape and optimum refrigerant flow rate are used to efficiently compress refrigerant gases regardless of the operational point. We continually employ the latest analysis technologies to evolve to solution so that high performance can be demonstrated under all conditions.

Enabling integrated optimum control of heat sources in combination with Ene-Conductor

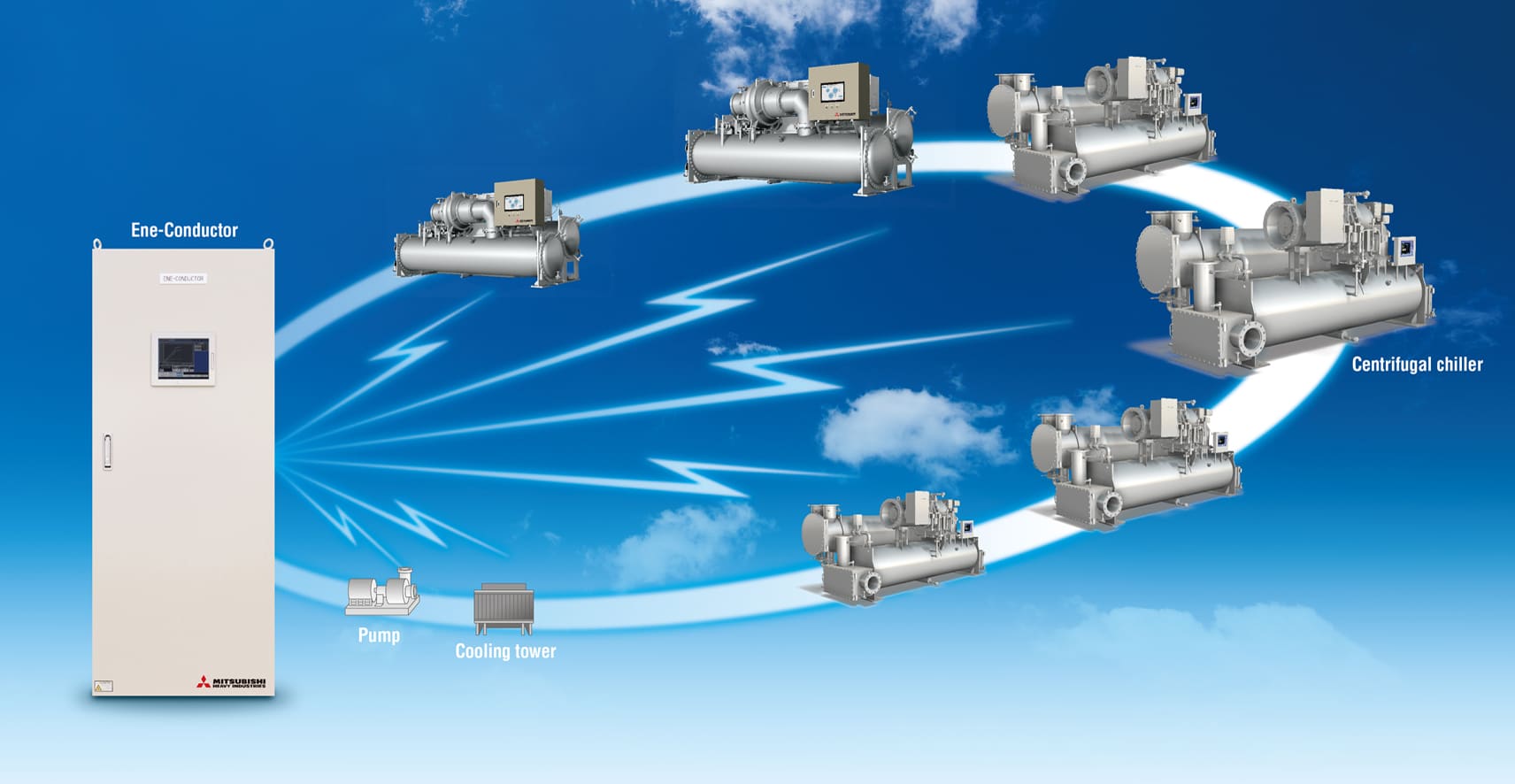

Installing the Ene-Conductor integrated heat source control system together with a Centrifugal chiller from MHI Thermal Systems enables the integrated control of heating and cooling source systems and maximizes Centrifugal chiller performance. To enable the optimum operation of heat source systems year-round, it is essential to monitor the operating status of chillers, and to be able to modify parameter settings from time to time. By having the chiller communicate with the Ene-Conductor in real-time, it is possible to automatically configure operating parameters that achieve energy efficiency based on chiller temperature settings changes around the year, rendering complicated operational management unnecessary.

Helping to stabilize equipment cooling heat sources with optional chiller function

By supporting the customization of high-speed chiller restarts, cooling water pools installed for the supply of cooling water at stable temperatures can be minimized. Through a high-performance microcontroller board and sensors installed within a chiller, the start-up load can be instantly tracked, enabling cooling water to be supplied at a stable temperature. Thanks to the support for ultra-low load, stable continuous operation even under idle load conditions can be achieved. We can also propose solutions to build equipment that stands up to the requirements of sudden start-ups.