Case study

Industry: Food Processing

ISSUE

- Low-GWP refrigerants are required, for global warming prevention and to conform to the Act on Rational Use and Appropriate Management of Fluorocarbons.

- Stable equipment operation is a basic requirement for a 24-hour factory operation.

- Some processes require chilled water near to 0ºC, whereas other processes require hot water, each of which needs individual equipment for each production line. Therefore, there are issues consolidating the control of heat sources.

- When the specified production volume is reached for a product, the preparation work starts for the next product, during which time the heat load for cooling/heating reduces to zero. The customer was forced to choose between two situations: If the chiller operation is stopped for energy-saving purposes during this preparation period, the equipment needs to be restarted later and it would take time for chilled water and hot water to reach the required temperatures. Alternatively, when the chiller runs without stopping, it would consume unnecessary standby power.

SOLUTION

KEY POINTS TO THE SOLUTION

- Optimizing the facility system

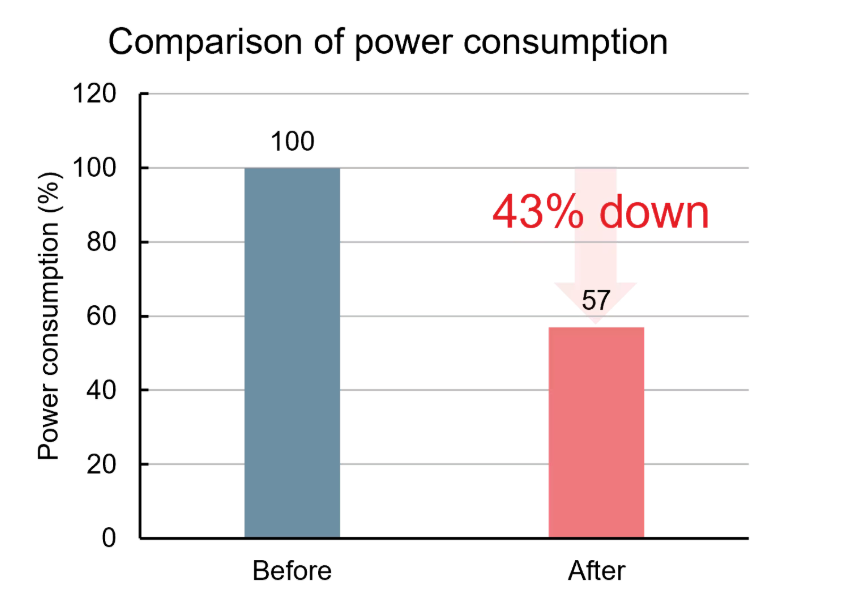

- Installing Centrifugal Chillers of “ETI-Z with HFO-1233zd (E)” and “GART-ZE with HFO-1234ze (E)” Refrigerant has realized environment-friendly operation, bringing a power consumption reduction of 43%.

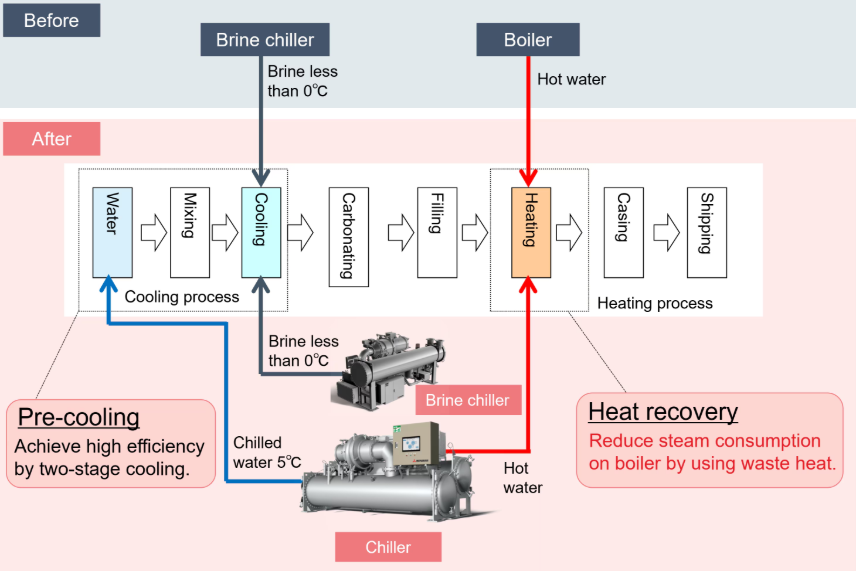

Optimizing the facility system

- A productheating is a following process of the upstream product cooling process, which means that the process line needed cooling and heating at the same time. As a solution, the waste heat generated from the upstream of chiller for cooling process was recovered and stored in a hot water tank, permitting a reduction of steam consumption as well as a reduction in the electricity consumption cost to generate the steam.

- Centrifugal chillers have better operational efficiency when there is small temperature difference between the chilled waer side and the waste heat side. Using this characteristic, the cooling process was separated into two stages to improve system efficiency:

- Pre-cooling with chilled water at 5℃, and

- Cooling with brine at 0°C or lower.

- Also, after the specified production volume was reached, there was batch operation such as sudden start and stop for a short period in order to prepare for the next production run. Introduction of the Ultra-Low Load Centrifugal Chiller can better handle such batch operation and allow optimized idle time for the equipment.

【Image for Plant System Flow】

Installing Centrifugal Chillers with HFO-1233zd (E) and HFO-1234ze (E) Refrigerant has realized two major objectives at the same time: energy conservation for an environmentally-friendly approach, and a 43% reduction in power consumption.

- The centrifugal chillers introduced in this case study realize a stable supply of chillerd water and brine at an optimum temperature and flow rate through cooperative control of the heat source as well as its auxiliaries, during the system’s production preparation, production, and finishing operations. As a labor saving measure, data from each operation wichi was previously recorded manually, is now automatic.

- Furthermore, the refrigerants HFO-1233zd(E) for ETI-Z and HFO-1234ze(E) for GART-ZE have a global warming potential GWP of 1 or less, and have characteristics of non-flammability, micro-combustibility, and low toxicity, and thus contribute to the reduction of global environmental impact. As the customer correctly grasped the operation status of the existing plant system, they applied an ideal combination of high-efficiency centrifugal chiller and centrifugal chiller at ultra-low load. This choice has realized a 43% reduction of power consumption compared to that achieved by the conventional system, a significant contribution to energy-saving of the plant.

【Reduction for power consumption after introducing centrifugal chillers with HFO-1233zd(E) and HFO-1234ze(E)】

EXPECTED OUTCOME

- Contribution to global environment through introduction of equipment having low environmental impact.

- Improved awareness and presence among stakeholders as a company embracing best environmental practices.

- System based labor-saving approach achieved through introduction of latest chillers into the existing facilities as an update.

- Consolidated control of production line heat sources achieving a power consumption reduction of 43% compared to that obtained by the conventional facility, so contributing to the energy-saving of the entire plant.