Case study

Ikebukuro District Heating and Cooling Co., Ltd.

| Project | Modification of the Large Capacity 2700 RT Centrifugal Chiller to a Variable Speed Drive |

|---|---|

| City/Country | Tokyo / Japan |

| Implemented solution | Modification of an Existing Constant Speed Centrifugal Chiller to a Variable Speed Drive |

ISSUE

Higher efficiency and energy-saving for a district heating and cooling system with high heating and cooling demand

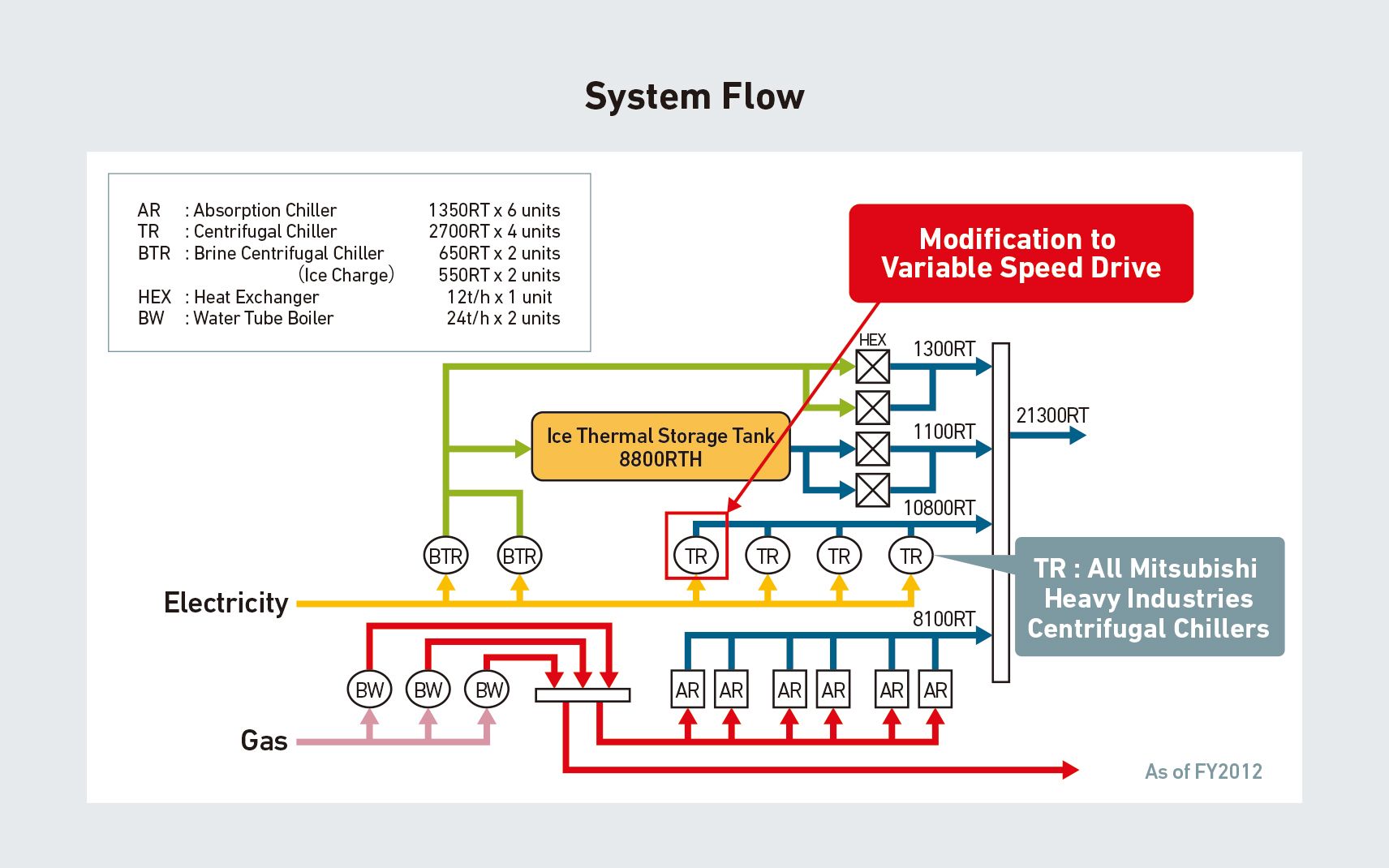

Ikebukuro District Heating and Cooling Co., Ltd. contributes to local development in the Higashi-Ikebukuro area by stably supplying chilled water and hot water for 24 hours, 365 days. There are four centrifugal chillers with a total capacity of 10,800 RT, six absorption chillers with a total capacity of 8,100 RT, and an ice thermal storage system for chilled water supply. Mitsubishi Heavy Industries Thermal Systems (MHI Thermal Systems) delivered four constant speed centrifugal chillers with a total cooling capacity of 10,800 RT (2,700 RT/unit) in 2002, however, there were further needs to improve energy efficiency throughout the year. Theoretically, the lower the cooling water entering temperature is, the higher the efficiency of the centrifugal chiller will be, which should lower power consumption. However, because of the centrifugal chiller's original specification limitations at the time of delivery, the customer needed to adjust the cooling water entering temperature 20℃ or higher. For this reason, consideration was given to operating the centrifugal chiller with a cooling water entering temperature of 20℃ or lower during the intermediate months and winter months.

SOLUTION

KEY POINTS TO THE SOLUTION

- Modification of an existing centrifugal chiller to a variable speed drive

- Significantly improved part load performance by enabling operation at low cooling water entering temperatures

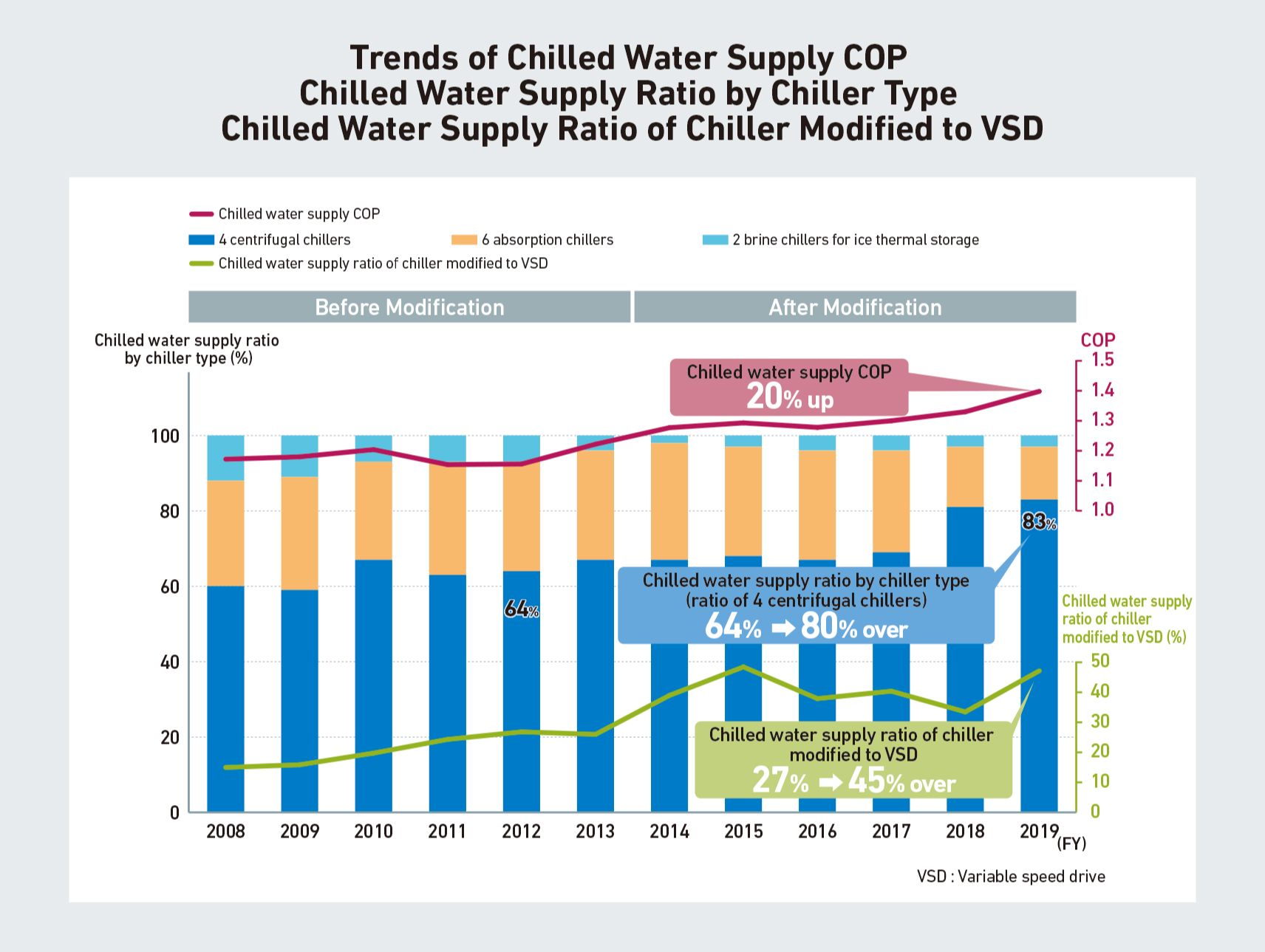

- More efficient and energy saving operation by improving an annual chilled water supply COP by 20%

Modification of an existing centrifugal chiller to a variable speed drive

Ikebukuro District Heating and Cooling Co., Ltd. had been operating four centrifugal chillers manufactured by MHI Thermal Systems, however, most of them were being operated under part load conditions with a cooling water entering temperature of 20℃. To resolve it, one of the four constant speed centrifugal chillers has been modified to a variable speed drive, which would enable a high-efficient operation under part load conditions and a cooling water entering temperatures of 20℃ or lower.

Significantly improved part load performance by enabling operation at low cooling water entering temperatures

The Coefficient Of Performance (COP) before the modification of an existing constant speed chiller showed the highest point at the approximately rated 100% capacity. After the constant speed chiller was modified to a variable speed, the customer could operate the chiller with the cooling water entering temperature at 13℃, while part load performance significantly improved, improving to a maximum of over 14.

More efficient and energy saving operation by improving an annual chilled water supply amount COP by 20%

The operation data for FY 2019 shows that centrifugal chillers had been operated more than absorption chillers. In terms of the chilled water supply amount percentage of respective chiller, centrifugal chillers accounted for more than 80% of the total chilled water supply amount, and among that, the chilled water supply amount generated by the centrifugal chiller modified to the variable speed accounted for nearly half of such amount. By improved and optimized plant operational efforts to increase operating hours for the variable speed centrifugal chiller with more efficient part load performance while reducing operating hours for other type of chilled water supply equipment, the chilled water supply system COP has been improved by approximately 20% compared to that before the modification of variable speed drive. The modification of an existing constant speed chiller to a variable speed has contributed to the customer’s annual energy savings.

OUTCOME

- To Reduce the environmental impact by reducing CO₂ emissions through energy savings

- To Reduce mid/long-term operational cost with improved efficiency of existing chillers

- To Contribute to customer's increased brand value as a green company that takes necessary actions to save energy

CUSTOMER VOICE

Ikebukuro District Heating and Cooling Co., Ltd. has a long history and track record of providing stable heating and cooling supply to users in the Higashi-Ikebukuro area since 1978. The power shortages that followed by the 2011 Great East Japan Earthquake caused consumers to accelerate their electricity and energy saving efforts. This caused cooling loads to fall below expectations, therefore, our plant faced an urgent need to improve its operating efficiency in the low-load range. To do this, it led us to draw up a plan to modify an existing centrifugal chiller to a variable speed drive. When modifying an existing plant to include a variable speed drive capability in the middle of the large city, there are usually space and other constraints that we would face. For example, its delivery, unloading and installation layout had to be considered for the variable speed drive panel, which was larger than the existing panel, and existing electrical equipment had to be modified accordingly. We worked closely with the designers and engineers from MHI Thermal Systems to hammer out each issue. We also made efforts to find out the optimized plant operation method through trial and error after the modification of an existing constant speed chiller to a variable speed chiller installed, resulting in energy savings in line with expectations, so we are thoroughly satisfied with the modification to a variable speed drive. As a district heating and cooling operator responsible for a city’s infrastructure, we will take environmental responsibility fully into account when providing a stable supply of chilled water and steam according to the growth and change of the city. To support these needs, we expect that MHI Group will continue to develop greener products that are easy for a district heating and cooling operator to use and has lower environmental impact, as well as providing maintenance service that respond quickly if there is any problem with us. We hope that MHI Group will continue close relationship where we can trust and work comfortably with each other.