Case study

RM TOHCELLO CO., LTD.

| Project | BCP and energy conservation projects (Energy service provided by Tokyo Gas Engineering Solutions Corporation) |

|---|---|

| Location | Itako Works / Ibaraki / Japan |

| Industry / Sector | Production and distribution facility for packaging films and foam sheeting for food and beverages products, daily necessities and packing materials |

ISSUE

Balancing power supply stability with economic and environmental considerations

The facility did not have access to sufficient commercial power supplies nearby, and the area was subject to frequent lightning strikes. We were using diesel cogeneration systems designed to switch to independent operation in an emergency to prevent a voltage drop or total loss of power. Toward the end of our diesel engine cogeneration system contract, we started exploring the feasibility of moving to a more cost-efficient gas engine system with lower carbon emissions. The facility did not have access to sufficient commercial power supplies nearby, and the area was subject to frequent lightning strikes. We were using diesel cogeneration systems designed to switch to independent operation in an emergency to prevent a voltage drop or total loss of power. Toward the end of our diesel engine cogeneration system contract, we started exploring the feasibility of moving to a more cost-efficient gas engine system with lower carbon emissions.

SOLUTION

KEY POINTS TO THE SOLUTION

- Boosts BCP by providing a stable power supply to production lines in the event of disruption to commercial power

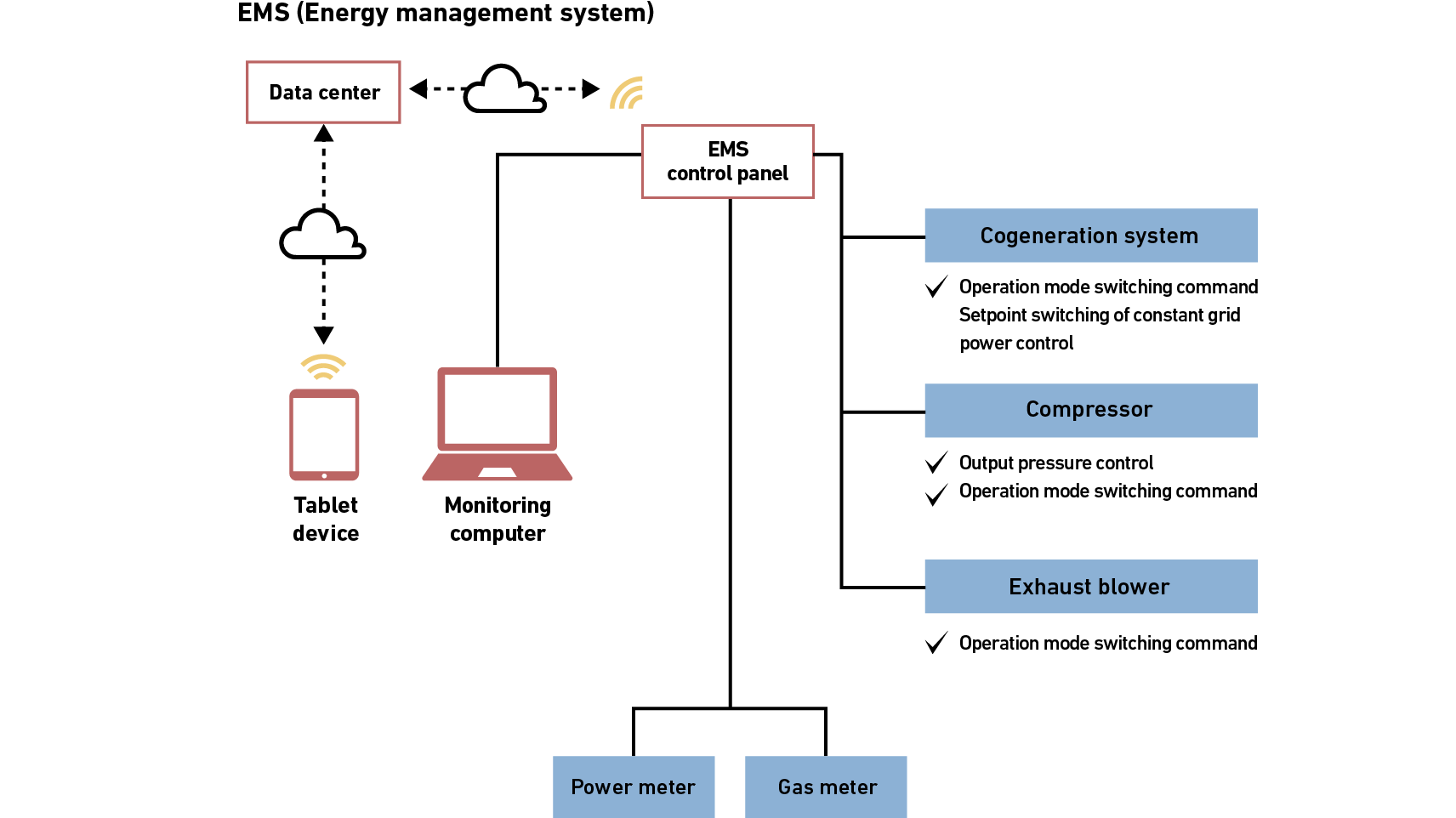

- Improves overall efficiency through effective utilization of waste heat from gas engine combined with energy management system (EMS)

- Reduces CO₂ emissions thanks to eco-friendly gas engine

Boosts BCP by providing a stable power supply to production lines in the event of disruption to commercial power

The MHI gas engine cogeneration system is designed to ensure stable power in an emergency. In order to alleviate client concerns about the ability of the gas engine to track load fluctuations to the standard of commercial power, together with the associated risk of power loss during an emergency, MHI undertook a detailed monitoring study of power loads at the client facility. We also developed a test engine and performed a range of tests. Following modifications to the engine specifications and the sequence of operations (or procedures), we successfully demonstrated that the system can provide a stable power supply in the event of sudden fluctuations in power load. We also showed that installing multiple gas engine cogeneration systems acts as a risk hedge to prevent a full power blackout in the event of a fault or failure. This reliable and dependable BCP solution from MHI is now on the market.

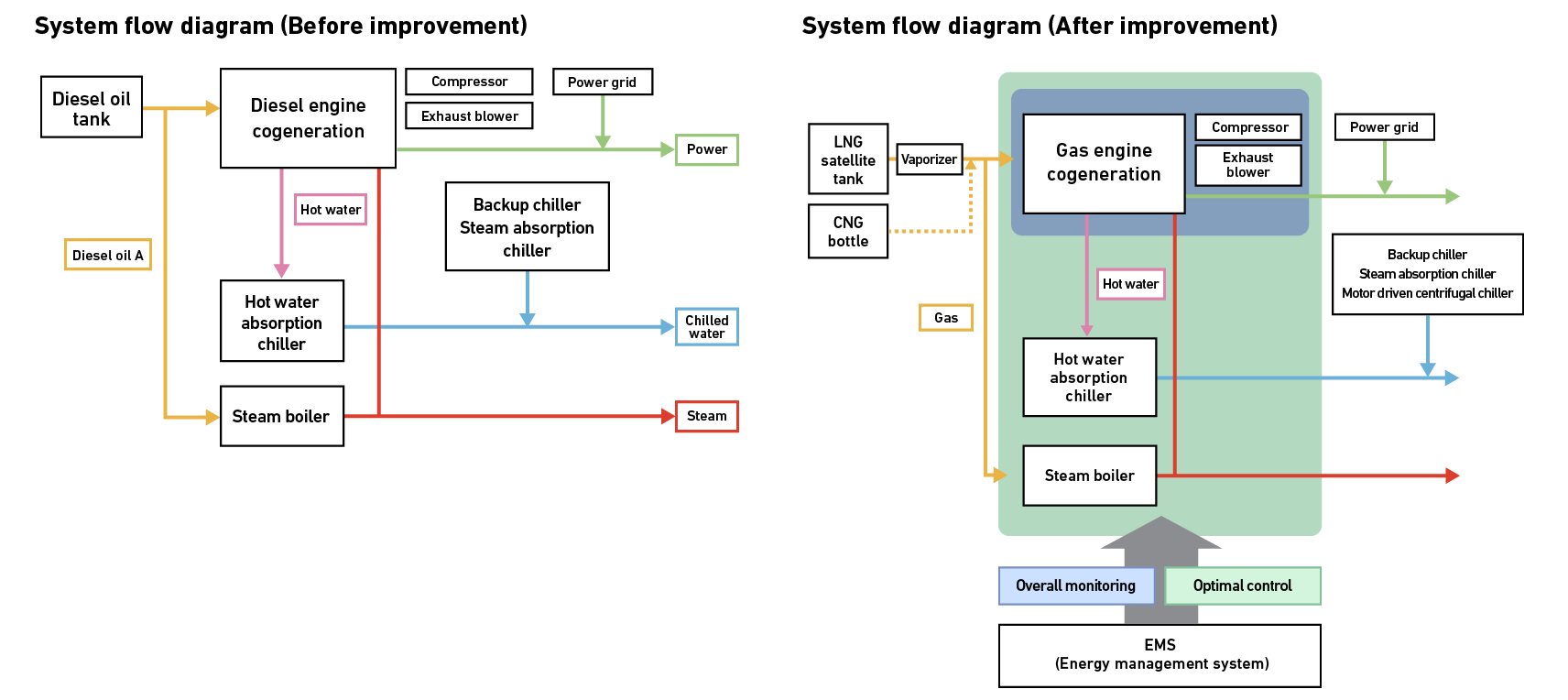

Improves overall efficiency through effective utilization of waste heat from gas engine combined with EMS

The gas engine cogeneration system developed by MHI uses cooling water from the gas engine (discharged as hot water) for refrigeration and gasification of liquefied natural gas (LNG). This delivers overall efficiency superior to conventional gas engine monogeneration systems. The Energy Management System (EMS) enables efficient energy management by displaying graphs of key data trends such as cooling load and air consumption. EMS data is also used by the gas engine cogeneration controller to optimize energy efficiency and significantly reduce operating costs.

Reduces CO₂ emissions thanks to eco-friendly gas engine

Gas engines run on LNG fuel, which has a lower environmental impact, and therefore have lower CO2 emissions than diesel engines. The high-efficiency gas engine cogeneration system from MHI generates cleaner emissions through the use of optimized fuel combustion. In this way, we have been able to reduce emissions of both CO2 and NOx (nitrogen oxides).

OUTCOME

- Guarantee of stable power supply in emergencies improves BCP

- High-efficiency heat recovery saves energy and reduces operating costs

- Lower emissions of greenhouse gases (GHG) including CO2

CUSTOMER VOICE

Our Itako Plant is located in an area subject to frequent lighting strikes. Previously we were using diesel engine cogeneration systems and switching to independent operation to avoid sudden voltage drops caused by power blackouts. We had considered switching to gas engine cogeneration systems, but were concerned about the ability of gas engines to accurately track changes in power load, given that efficiency is the top priority. MHI conducted a series of tests using a test engine, and then introduced a series of modifications designed to deliver the required load-response performance without impacting on efficiency. We switched to gas engine cogeneration systems, which have reduced our energy consumption and significantly lowered our CO2 emissions. In combination with subsidies, we have also been able to reduce our overall expenditure on energy services. The EMS generates a range of data graphs that make it easier to manage our energy usage. With the EMS, we will continue to save energy for years ahead.