Solution

Next step to reduce GHG emission

In our daily life, we would see the impact of global warming across various media. This warming is due to CO2 and other greenhouse gas emissions, and the several countries of Southeast Asia have announced carbon neutrality plans by 2050, and are accelerating the transition. How is your company working to reduce GHG emission? Despite changing to energy saving products such as LED lightings and using solar power as a first step, customers struggle with the next steps of energy saving and many had reached out to us requesting for practical solutions to reduce GHG emission. Mitsubishi Heavy Industries,Ltd.(MHI) and its group companies would offer several solutions such as Chiller, Co-generation, Organic Rankine Cycle (ORC) and Energy Management Systems (EMS) by energy-saving, waste heat recovery and so on to reduce the GHG emission and the energy cost.

FEATURES

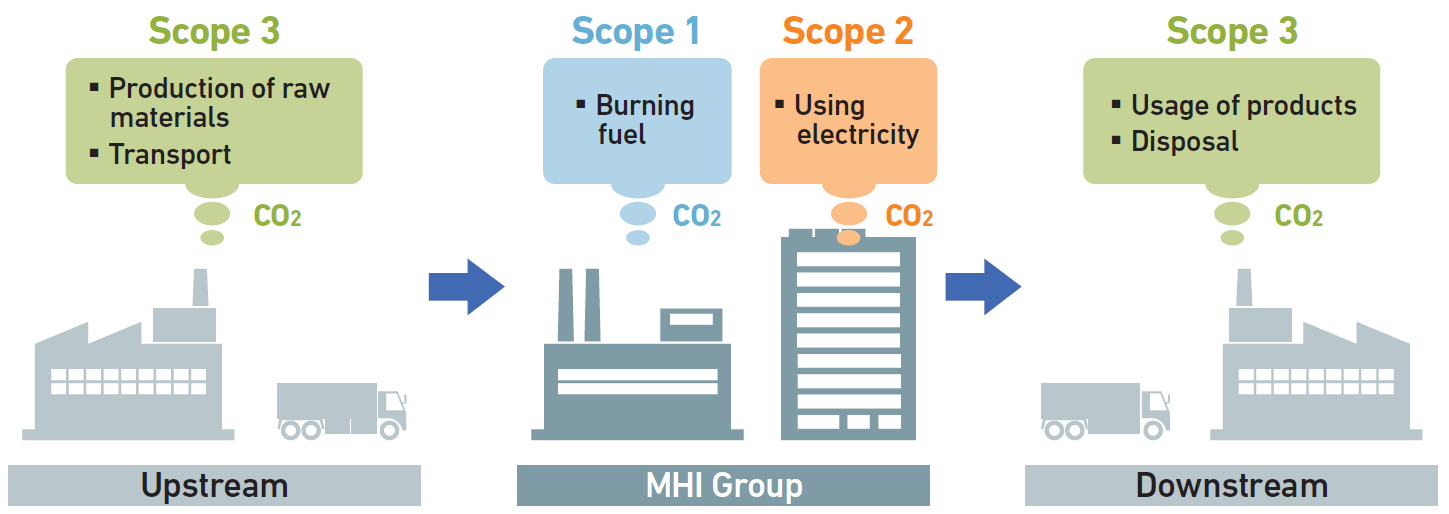

GHG emissions and Scope1,2, and 3

Considering the amount of emissions throughout its life cycle, whole of “supply chain”, the framework of “Scope 1, 2, and 3" is internationally recommended as a standard for the calculation of GHG emissions. Scope 1, Scope 2, and Scope 3 are the ways of understanding GHG emissions in the supply chain from production to disposal. This is stated in Greenhouse Gas Protocol, an international standard for calculating and reporting GHG emissions. Scope 1: Direct emissions of CO2 by the company itself, which is mainly generated by fuel combustion. Scope 2: Indirect emissions connected to the use of electricity, heat, and steam supplied by other companies. These emissions mainly arise from the consumption of electricity. Scope 3: Emissions of other companies both of upstream and downstream for the company’s supply chain.

Impactful GHG emissions reductions for industry

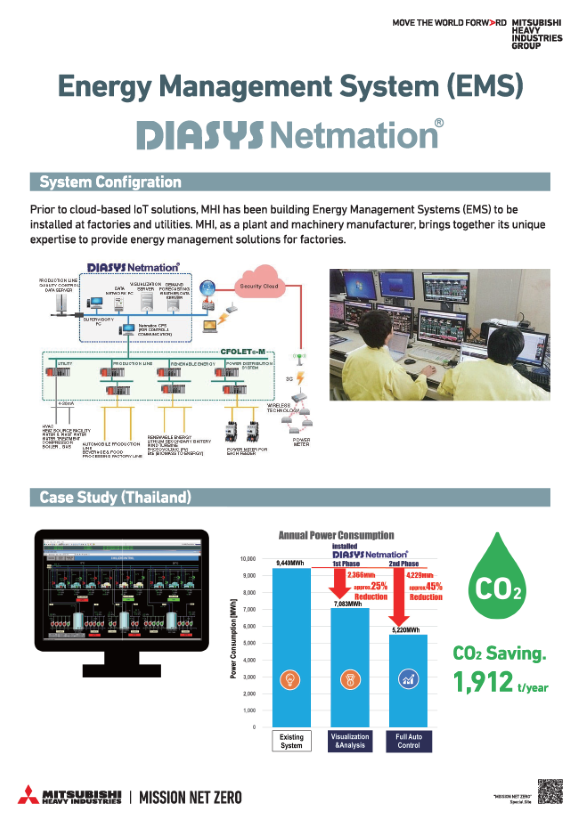

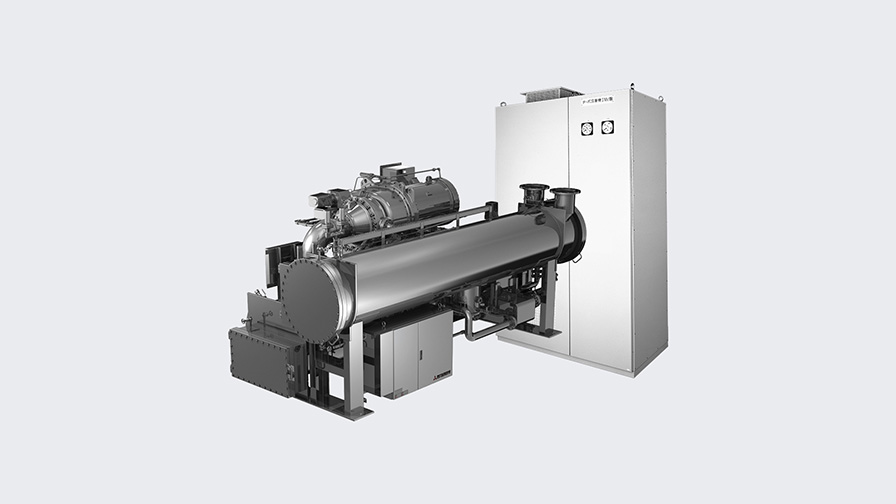

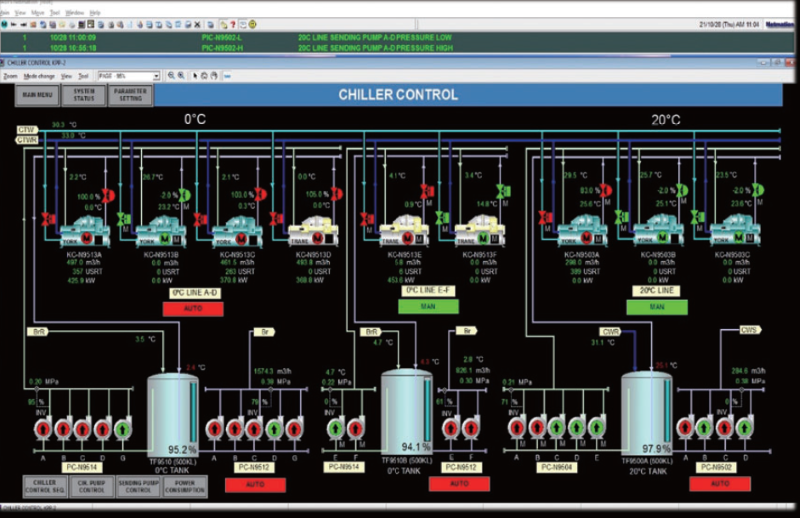

MHI is actively promoting energy transition initiatives which contribute towards the decarbonization of existing infrastructures. Additionally, MHI offer various decarbonization and energy-saving solutions for industrial customers, enabling them to reduce their Scope 1 and Scope 2 emissions. MHI is committed to support our customers in their efforts to achieve their respective decarbonization goals. Scope 1 : Centrifugal Chiller : Implementing high-performance and energy-efficient centrifugal chillers enables substantial power consumption reductions for factory customers. Scope 2 : Energy Management System (EMS) : EMS enables visualization and control of power consumption in factories, optimizing energy usage for improved efficiency. Gas Engine Co-generation : replace existing coal-fired boilers with gas engine cogeneration to reduce grid electricity consumption and contribute to the reduction of scope 2 emissions. Gas Turbine : The implementation of small gas turbines is also effective for factories with a certain level of power demand. This enables reductions in grid electricity consumption and Scope 2 emissions, contributing to overall energy efficiency. ORC (Organic Rankine Cycle) : ORC is a technology that enables the recovery of excess waste heat in factories, allowing for electricity generation without the need for additional fuel. This contributes to reductions in grid electricity consumption and Scope 2 emissions.

Solution in Scope1

Centrifugal Chiller

Solution in Scope2

Energy Management System (EMS)

Gas Engine Co-generation

Gas Turbine (H-25)