Solution

Optimization of load matching and stable operation with multiple H-25 gas turbines

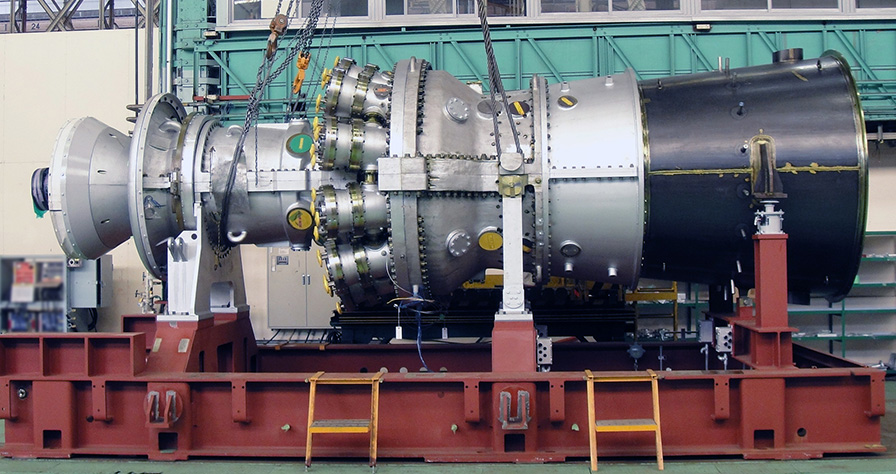

Converting an existing power station to a gas-fired combined-cycle plant with H-25 improves thermal efficiency by 50% and load-following capability.

FEATURES

Maintaining the competitive thermal efficiencies over a wide load range, while achieving flexible operation in response to demand fluctuation

By adding 6 units of H-25 gas turbines and a HRSG connecting the plant’s existing steam turbines, it is possible to convert an existing 132MW plant into a 225MW combined cycle plant at 50% better efficiency. One advantage to using multiple small gas turbines is that “it allows the plant to maintain competitive thermal efficiencies in incremental blocks of power over a wide load range starting at around 20MW on up through 225MW.” Once-through stream generators are applied as HRSG because they simplify plant design and installation, are easy to operate, and can run dry to serve as a gas turbine exhaust stack without having to generate steam. A single operator can start as many as five units at one time and switch to simple cycle operation without having to bypass the gas turbine exhaust. In addition, the once-through design enables fast response to changing load demand and facilitates shutdowns even at minus 40℃ ambient air temperatures. The repowering option proved to be the most feasible in terms of cost, efficiency, operating flexibility, scheduling, and meeting environmental regulations. *In some part, the article utilizes the past issued article in Gas Turbine World magazine.

Long Term Service Agreements (LTSA) provide comprehensive maintenance support

LTSA enables plant operators to shift tasks traditionally performed by themselves, such as planning of scheduled inspections, procurement of repair parts, and maintenance to the OEM ensuring the stable and efficient operation of the plant. This approach also reduces plant-side risks in the form of ordering and planning errors, which can interfere with scheduled inspections. This results in significant reductions in the workload associated with plant maintenance.