Solution

Digital solution for performance improvement in partial load operation

With the intermittent nature of renewable electricity generation technology and the ever-changing demands of the grid, IGV (Inlet Guide Vane) Optimization is a digital solution that can help to meet these challenges. It is a control modification that closes the gas turbine inlet guide vanes in a controlled way to reduce air flow at partial loads and thus increase exhaust temperature while minimizing emissions.

FEATURES

Increase plant efficiency by optimizing IGV

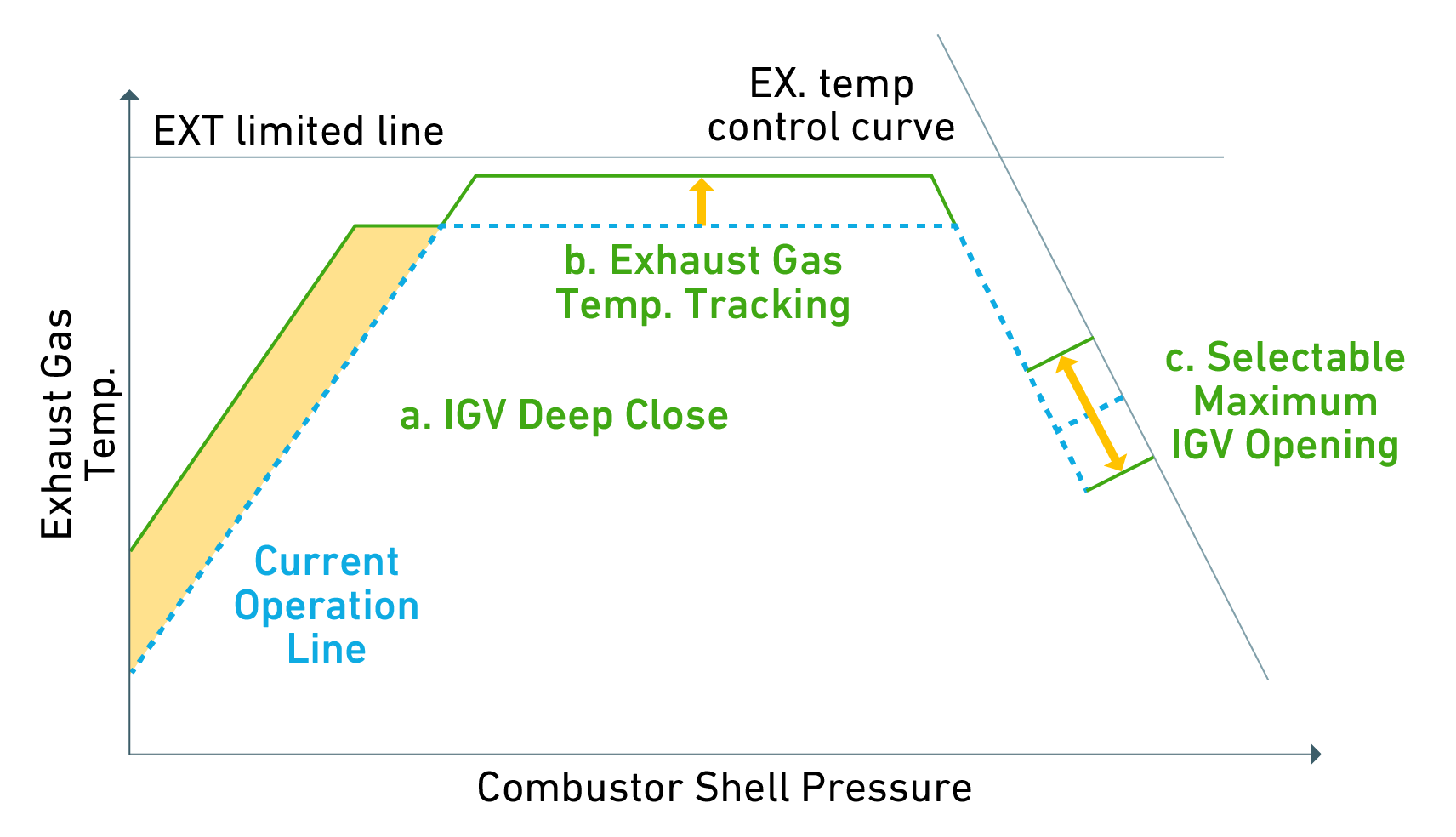

From the perspective of safety and reliability, Mitsubishi Power gas turbines have two control limits on exhaust gas temperature to keep turbine inlet temperature and exhaust gas temperature within design limits. In partial load operation, by raising the temperature of exhaust gas within the range such that the limit is not breached, the steam flow rate and temperature supplied to Steam Turbine (ST) are raised, which contributes to the improvement of ST output and plant efficiency.

3 menus are available as IGV Optimization in each load band

a. IGV deep close b. Exhaust gas temperature tracking (TOMONI Application) c. Selectable maximum IGV opening (TOMONI Application)

Since the available IGV setting depends on the customer requirement and unit specification, Mitsubishi Power can prepare the best plan in accordance with the customer’s requirements.

Tracking exhaust gas temperature can contribute to cutting CO emissions

In addition to the performance improvement, the control change also contributes the combustion temperature rising, resulting in the reduction of CO emissions.

EXPERIENCES

IGV Optimization has been installed on 51 units worldwide (as of Oct. 2021).