Solution

Ene-Conductor packs comprehensive expertise into a single package, saving energy and reducing CO₂ emissions

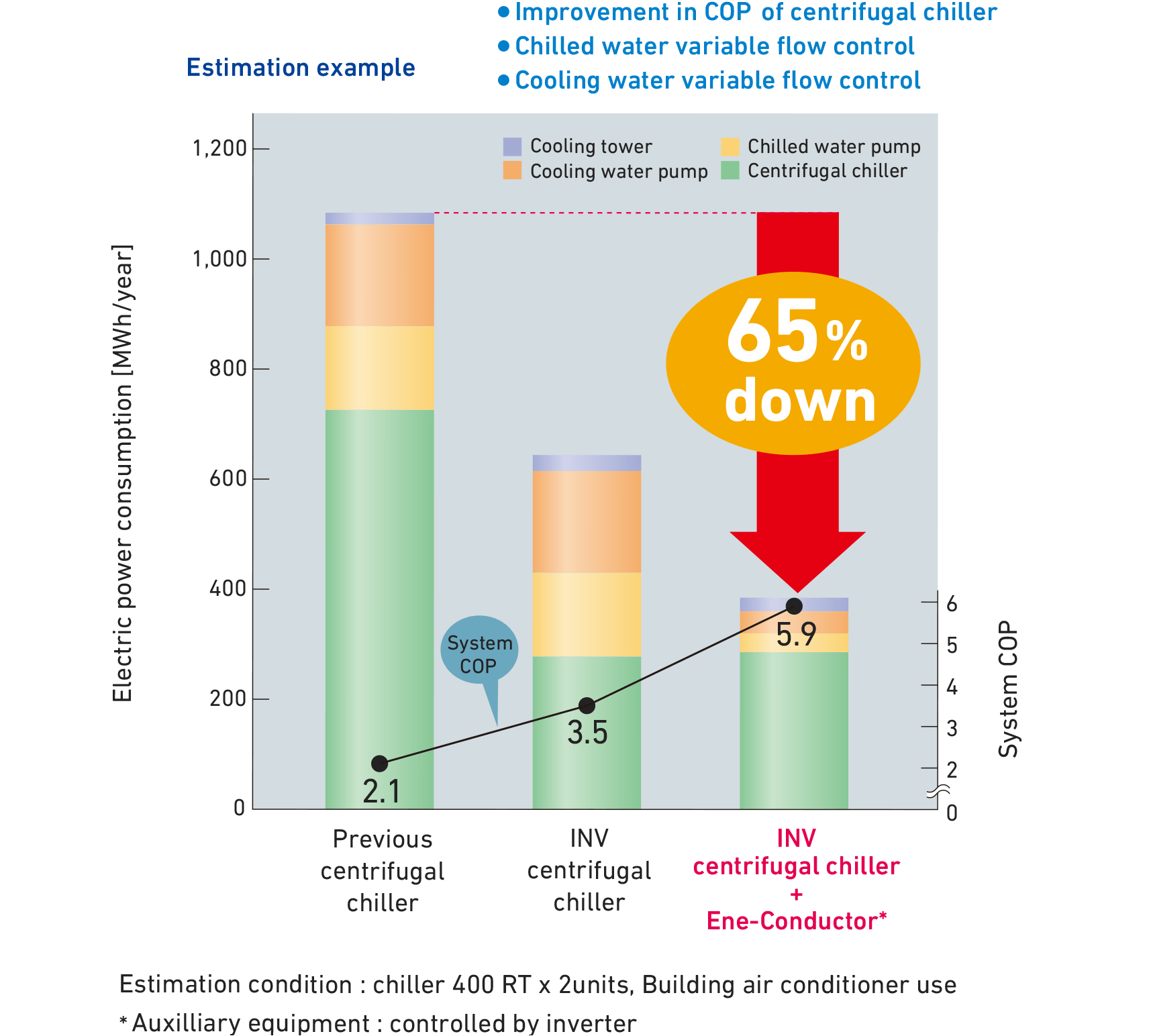

The Ene-Conductor is a total solution for the chiller control system of centrifugal chillers and associated equipment. By enabling the entire heating and cooling source system to be controlled by a single package while exercising optimum control over the entire system, the Ene-Conductor maximizes chiller performance. The Ene-Conductor delivers overall electricity savings of around 65% compared to existing turbo chiller systems, helping to conserve energy and reduce CO₂ emissions.

FEATURES

Optimized control maximizes chiller performance and system COP

The Ene-Conductor is able to optimize chiller performance by exchanging a large amount of operational data with the chiller unit and running control calculations. Even in systems that include multiple chillers, each with a different optimum loading, the Ene-Conductor automatically calculates the load distribution that maximizes the Coefficient of Performance (COP) of the system as a whole. By continually exercising optimized and efficient control, the Ene-Conductor delivers significant energy savings.

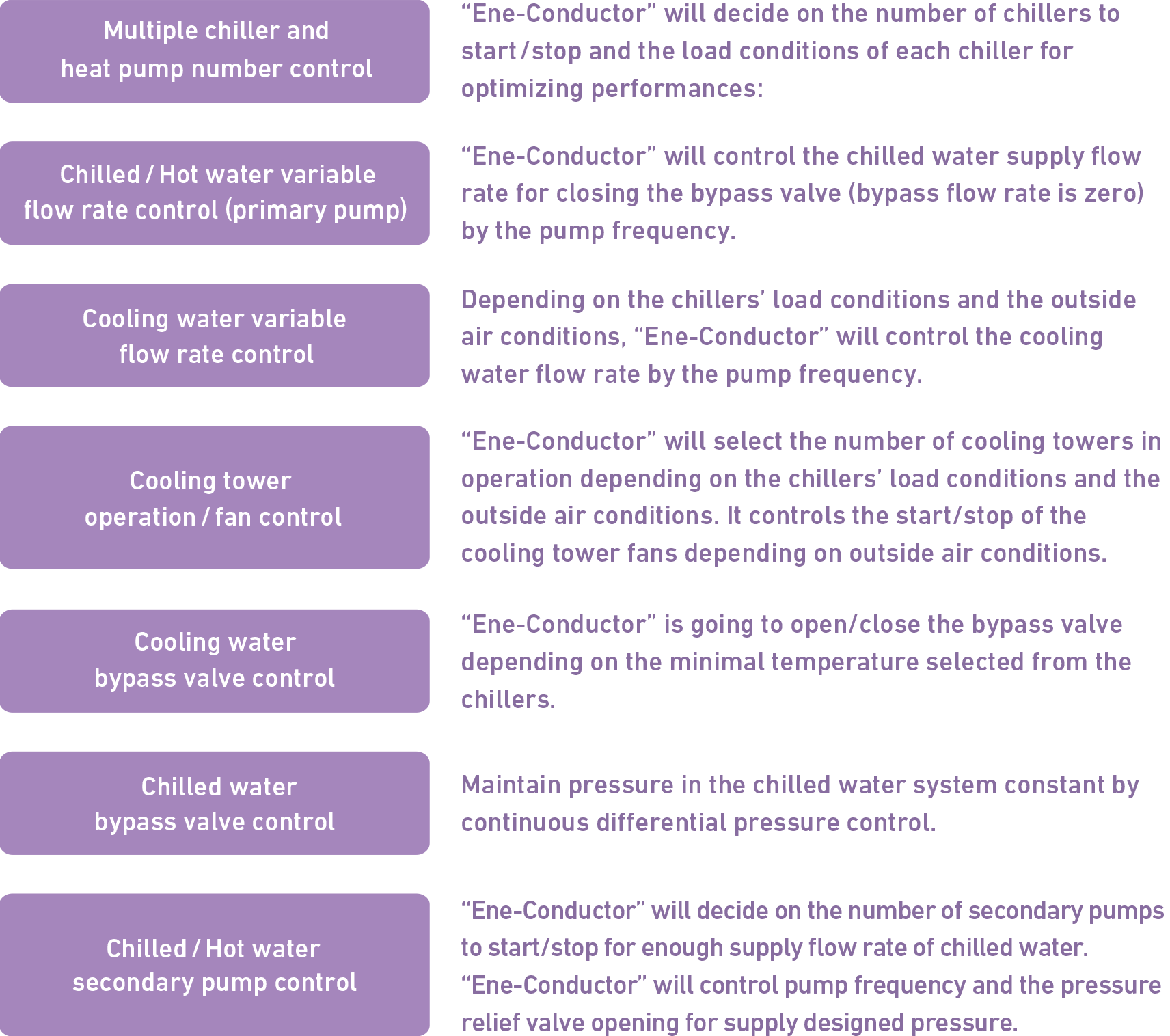

A comprehensive suite of energy saving features

By combining all the software necessary to control chiller equipment in a single package, the Ene-Conductor makes system design and installation a breeze.

Remote monitoring (internet connection) option

The Ene-Conductor uses a local area network to enable visualization of system status, enabling remote monitoring, thereby improving efficiency and enabling immediate response to problems.

Central monitoring function and connection to master unit (optional)

The Ene-Conductor can also be connected to a centrally-monitored programmable logic controller (PLC), enabling the status of all devices connected to the Ene-Conductor to be monitored from a central control room, so that they can be operated automatically while being monitored by an operator, and otherwise boosting efficiency and energy savings while reducing human resource requirements.

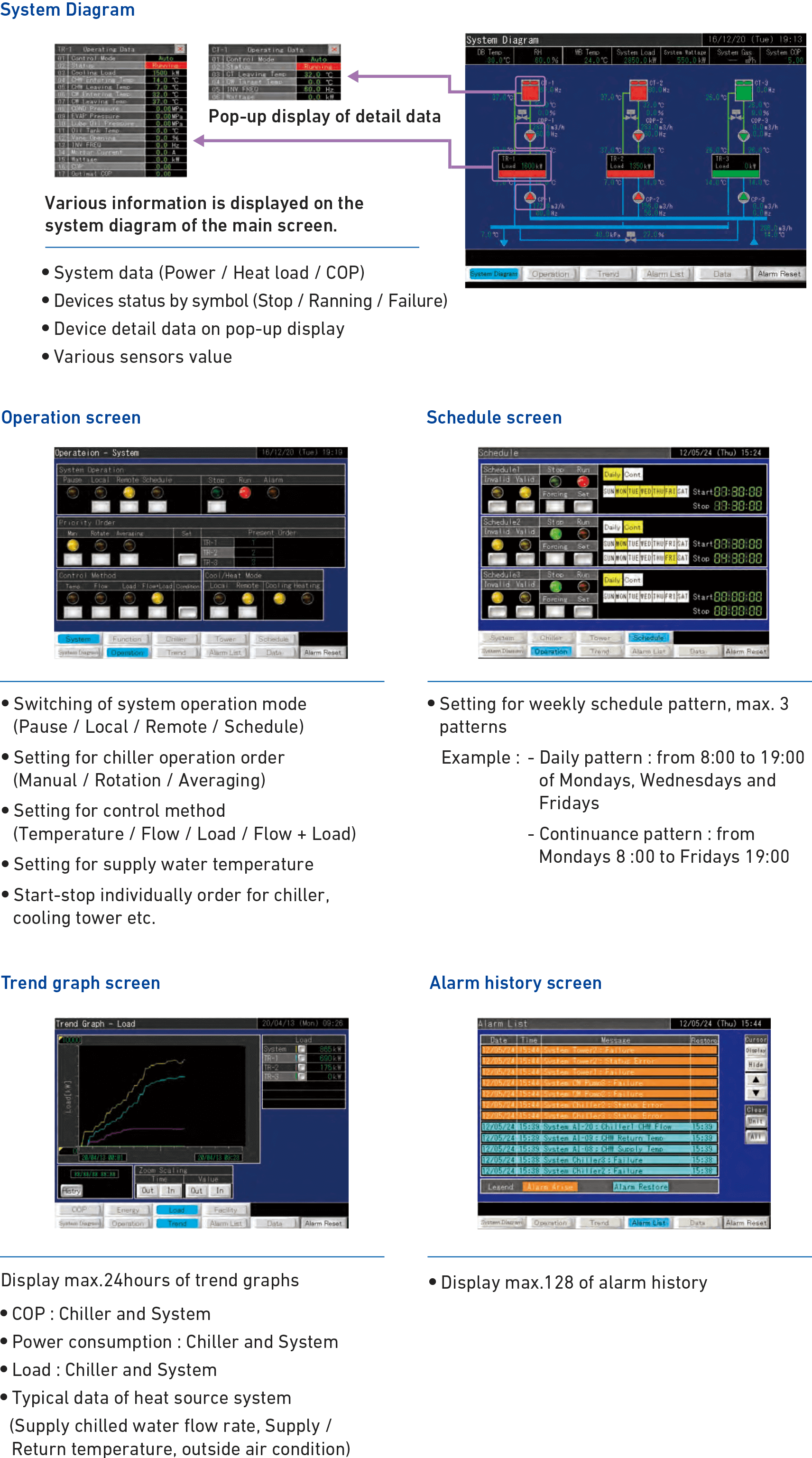

Superior user interface

The Ene-Conductor also improves convenience for users by replacing the traditionally complex user interface with a simpler interface. The interface comprises a 10.4 inch touch panel that can be used intuitively by anyone, offering superior operability, thereby facilitating operation.

All-in-one service from design to installation

Forget partial solutions. The Ene-Conductor allows you to optimize your entire system! MHI Thermal Systems offers an all-in-one-service that covers everything from fielding your chiller system requirements and precisely understanding your current situation to proposing an optimized solution, designing and installing the system, and offering ongoing support.

DOWNLOADS

Ene-Conductor: Heat Source Control System Catalogue

Mitsubishi Heavy Industries Technical Review, Vol. 51 No. 2 (2014) Feature on thermal technology

Ene-Conductor controller exercises optimum control over chiller systems that comprise centrifugal chillers