Solution

An advanced power plant control system that sets the course for a decarbonized society

Mitsubishi Power’s power plant control system “DIASYS Netmation®” is a solid foundation for rapidly evolving control technology and the latest applications needed to keep power plants reliable and secure in a rapidly decarbonizing energy system. It can be steadily updated to provide safe, secure, and stable operation of power plants. Building on this stable foundation with the optimal combination of TOMONI® intelligent digital solutions maintains high performance, avoids unplanned downtime, and enables sustained profitability increases. It also makes it possible to respond to future fuel conversions, thereby contributing to achieving a decarbonized society.

FEATURES

Enables flexible operation that meets society’s needs

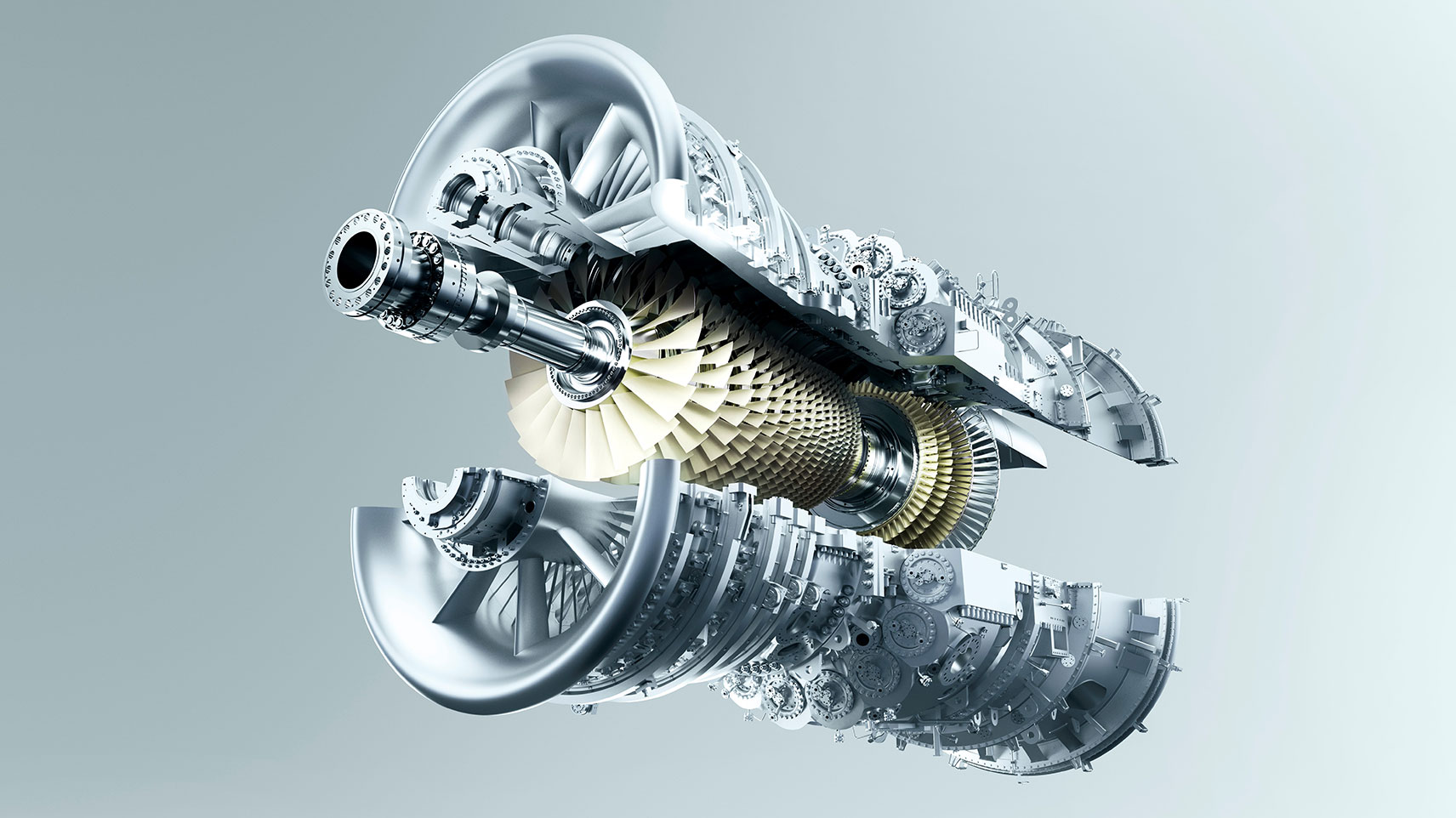

DIASYS Netmation® incorporates Mitsubishi Power’s gas turbine, thermal cycle and total plant design concepts in its control designs, making it possible to respond to advanced and complex requirements. These developments and modifications made by Mitsubishi Power based on a solid track record of numerous installations have yielded advanced control systems that only the original designer of the systems can provide. These systems are also agile in their response to control logic changes, enabling flexible operations for the changing needs of a decarbonized society. When conversions to cleaner fuels such as hydrogen and ammonia require the modification of power plants, operation is kept safe and stable by the maintenance and updating of the Netmation control system and the application of an optimal control logic. DIASYS Netmation® contributes to achieving a decarbonized society at several stages along the way.

TOMONI® keeps power plants operating optimally

The DIASYS Netmation® foundation enables the deployment and adoption of the latest intelligent digital solutions of the TOMONI® suite, which leverage the Operation and Maintenance (O&M) know-how cultivated over many years at Mitsubishi Power and proven at our T-Point GTCC verification facility. With its optimal control that considers the environmental conditions and operational situation at every moment, TOMONI® solutions enable operations that meet the evolving needs of power plant owners and operators. Remote monitoring, advanced analytics and expert support 24 hours a day, 365 days a year from the TOMONI® HUB and high-precision analysis and optimization functions preemptively detect and resolve potential issues. The issues are avoided, and power plant trips and load reductions are prevented while operating efficiency is maximized. Versatile and sophisticated optimal control is provided through a user-friendly interface. Deploying and adopting TOMONI® as part of an advanced power plant control system can lead to continuous profitability gains.

High reliability power plant control system

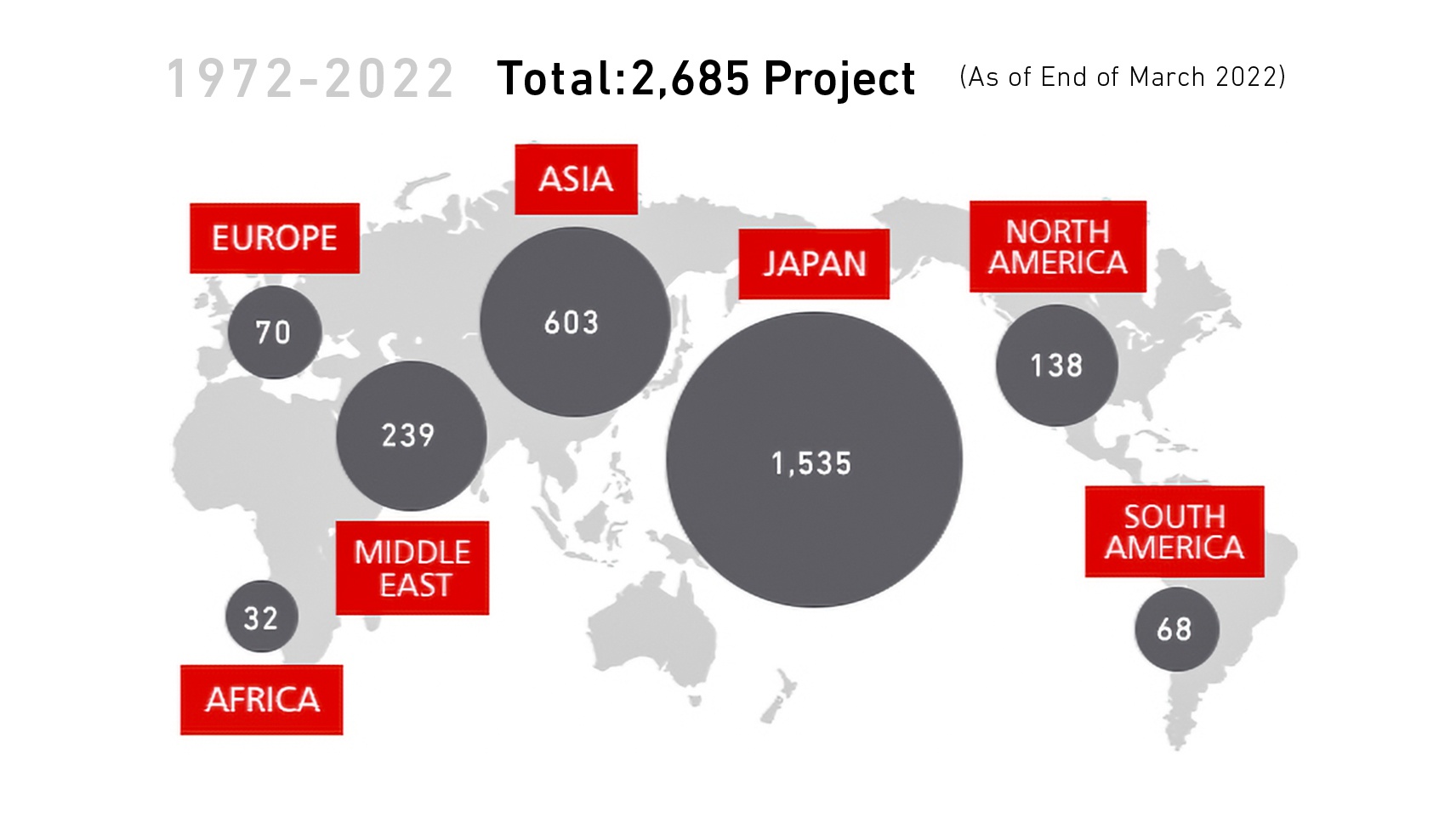

Developed in the 1980s as a control system for power plants, the DIASYS series boasts a track record of being adopted in over 2,600 projects not only thermal power plants but also a variety of complex facilities and products, including rocket launch facilities, LNG carriers, plant management systems and office building management systems. The high quality and low rate of component failure support the reliable operation of power plants around the world. The basic DIASYS Netmation® platform is steadily and carefully upgraded to take advantage of the latest proven technologies, operating systems and cybersecurity advances.

EXPERIENCES

DIASYS Netmation® has been adopted in over 2,600 projects.

FOR MORE INFORMATION

- Link to Mitsubishi Power website. Mitsubishi Power is a power solutions brand of Mitsubishi Heavy Industries.

- Mitsubishi Power Control Systems

CASE STUDIES

Electric power generation

The control system for power plants in a decarbonized society

This modern power plant control system responds to the needs of a decarbonizing society. It enables flexible operation and a smooth conversion toward clean fuels.

Electric power generation

How to strengthen cyber defenses and meet security requirements

How can power plants avoid possible unplanned downtime, equipment damage, financial losses and penalties when they fail to meet cybersecurity standards?