Solution

Catalyst performance management agency service for optimizing the operation and maintenance of SCR systems

“Optimization of SCR Catalyst Management” is a catalyst performance management agency service offered by Mitsubishi Power. As experts in SCR systems, we propose optimal operation and maintenance of SCR systems by the verification of the actual equipment performance based on the periodical catalyst sample testing and the DCS operational data.

FEATURES

Proposing the best SCR catalyst management service that meets customer needs

Mitsubishi Power has been developing and implementing SCR catalysts since the 1970s. We strive to develop new catalysts and improve them to accommodate customer needs. By managing the performance of SCR catalysts on your behalf, we help you minimize your investment for the catalyst by reduction of the replacement catalyst volume and prevents the loss of power generation profit caused by unplanned plant stop when switching fuels.

Residual performance estimation based on sample test

Using Mitsubishi Power's laboratory-scale catalyst evaluation system, we measure NOx removal efficiency, SO2 conversion rate, and analysis of the chemical components from the sample collected from your actual equipment. In addition to the laboratory-scale systems, we have various other test systems. By verifying the performance with the bench test system using a gas simulated as same as actual operating conditions, we are able to verify the residual performance. Based on the test results and the required performance evaluation for SCR operation, we can offer you an optimal maintenance plan accordingly.

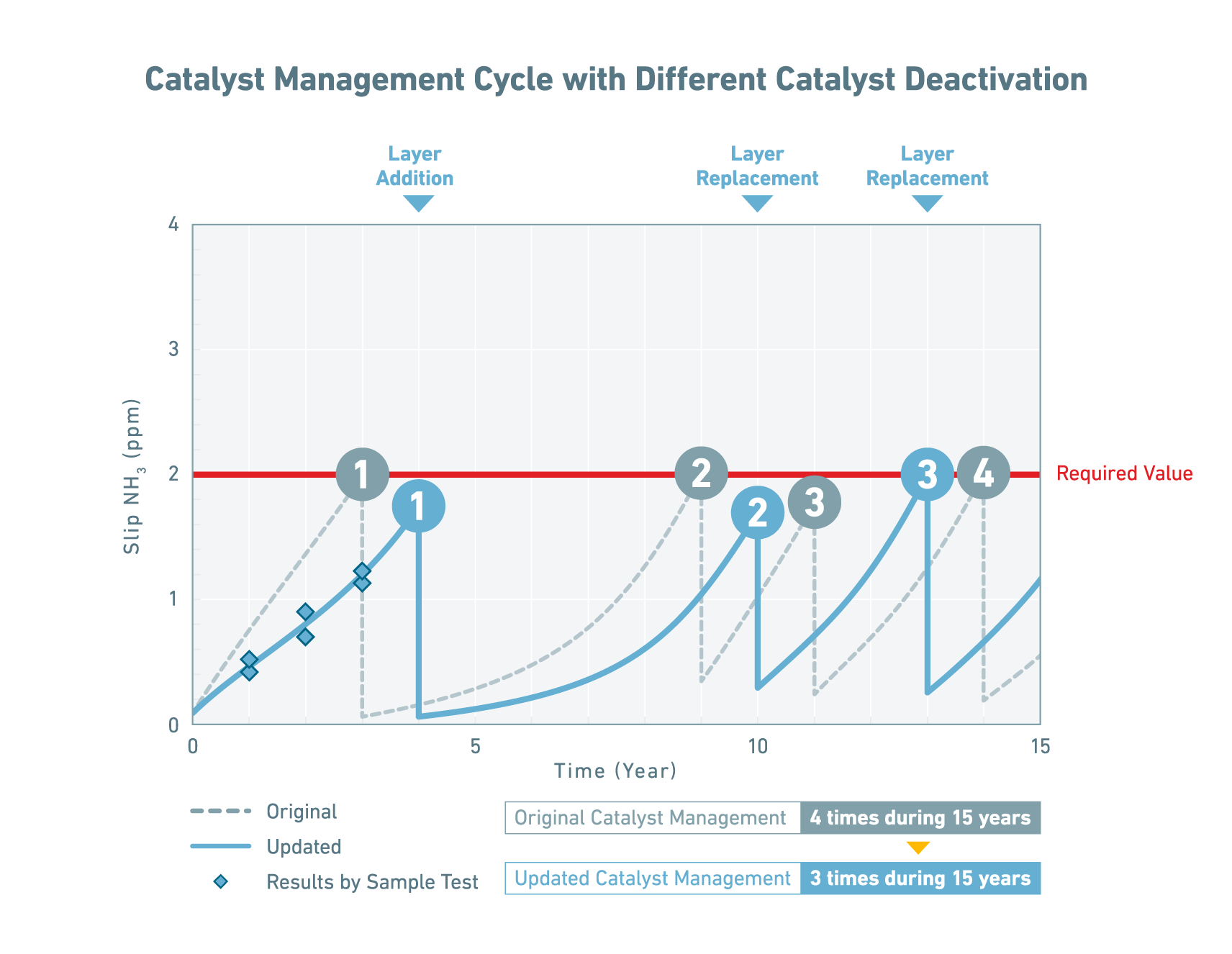

Evaluating SCR catalyst management plan when switching fuels

Mitsubishi Power analyzes the amount of catalyst poisons component in the fuel and estimates the lifespan of the catalysts based on the data we have accumulated so far on the effects of catalyst poisons on catalyst performance deterioration. Conducting optimal examinations and regular verification of operating conditions depending on each plant, we are able to create a plan for exchanging the right catalyst volume at the right time. This helps prevent the loss of power generation profit caused by unplanned plant stop due to performance issues.

Creating SCR catalyst management plan based on the plant operation plan

SCR catalysts are usually designed with 100% load exhaust gas conditions and account for excess against current operation conditions and low load operation. Therefore, we are able to review the catalyst volume required for exchanging from the current actual equipment operation data and the future operation plan. Since the optimal catalyst specifications differ between high-load and low-load operations, selecting the catalyst specifications based on the plant operation plan can help reduce the catalytic replacement amount. For example, if the boiler's load factor is reduced from 100% to 75%, the catalyst performance needed for operating the plant becomes lower, and the replacement catalyst volume can be halved over the span of 10 years.

EXPERIENCES

We have had an average of approximately 50 orders each year from our customers in Europe, the USA, and Asia between 2017 and 2021.

DOWNLOADS

FOR MORE INFORMATION

- Links to Mitsubishi Heavy Industries Group’s online media SPECTRA and Mitsubishi Power website.

- Selective Catalytic Reduction (SCR) System

- Optimization of SCR Operation and Maintenance / Catalyst Replacement

- Ensuring a green transition that works for all