Solution

Cost-efficient gas engine cogeneration systems for reduced CO2 emissions and improved BCP

Discover how MHI's gas engine cogeneration system ensures stable power, energy efficiency, and cost savings.

FEATURES

For Those Facing These Challenges:

- Struggling with Unstable Renewable Energy Supply — EBLOX ensures stable power through a hybrid system of solar, engine generator, and battery.

- Need Reliable Power in Off-Grid or Remote Areas — EBLOX delivers consistent electricity where grid energy is not available.

- Looking to Reduce CO₂ Emissions Without Sacrificing Performance — EBLOX balances environmental responsibility with operational efficiency.

Our Solution — GSR Series Gas Engine Cogeneration

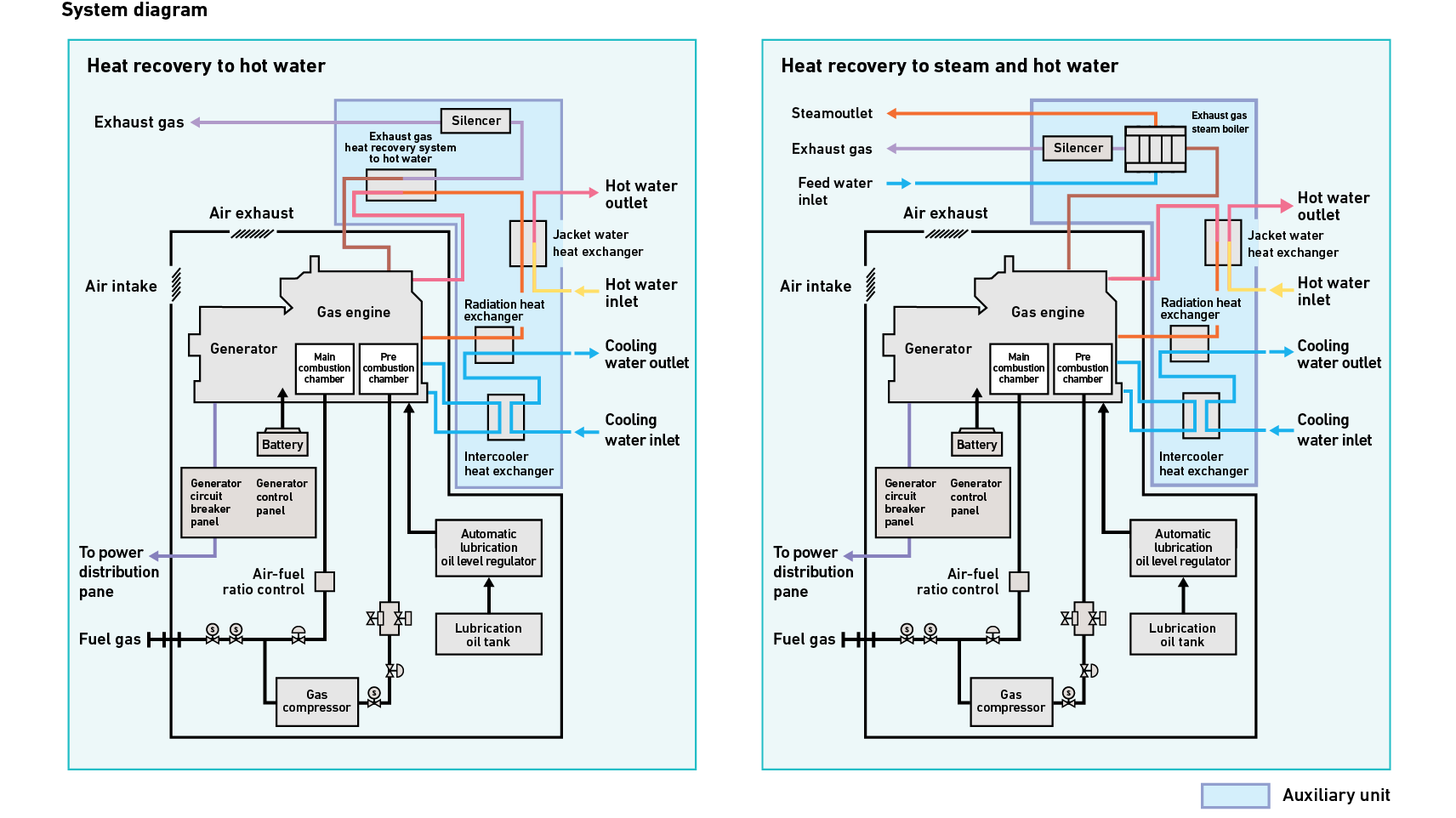

What it is: A continuous‑use gas engine cogeneration system that produces electricity and recoverable heat from one fuel source, designed to operate independently when commercial power is unstable or unavailable. Key Benefits (at a glance): ・Boosts BCP by providing a stable power supply to production lines in the event of disruption to commercial power ・Improves overall efficiency through effective utilization of waste heat from gas engine combined with energy management system (EMS) ・Reduces CO₂ emissions thanks to eco-friendly gas engine

How It Lowers Your Costs

Generate Power On‑Site: Reduce purchases from the grid by producing electricity with high engine efficiency. Recover Waste Heat: Use engine exhaust and jacket heat to produce process hot water/steam, displacing boiler fuel. Total efficiency >80% reduces combined electricity + thermal spend. Stabilize Operations: In outages, the system runs independently to avoid raw material loss and delivery delays.

Case Study (Japan) — Cost‑Efficient Cogeneration with Improved BCP

Customer: RM TOHCELLO Co., Ltd. (packaging films & foam sheeting for food/beverage/daily necessities) — Itako Works, Ibaraki. Challenge: Insufficient commercial power nearby; frequent lightning strikes. Needed a more cost‑efficient and lower‑carbon replacement for existing diesel cogeneration. Solution: Gas engine cogeneration with an energy management system (EMS) to improve overall efficiency and stabilize power to production lines during disruptions. Results: Stable power in emergencies with verified load‑following capability. Lower CO₂ and better energy economics via effective waste‑heat utilization and optimized engine sequencing.

Turn Rising Energy Costs into Today

Complete the form below and then press ‘Submit’. You will shortly receive a message confirming receipt of your inquiry. *Required

[PLEASE NOTE]Contact us

・This service is intended for corporate users.

Therefore, we may not be able to respond to inquiries from individuals or free addresses.

・For companies which we may determine as competitors or in the same line as our service, we may not be able to respond to your request.